I got a rare, mid-week chance to get in the shop. I've been obsessed with this idea of late for a system of tool holders for my walls. Right now I've got my chisels sitting on a shelf in the wall cabinet I got from my brother-in-law. That is way less-than-ideal. My idea, which I was starting to test out last night, is to make a basic frame that will hang on the wall with french cleats. Attached to this frame will be more french cleats in regular rows down the length of the frame. I could then use these cleats to hang various configurations and sizes of tool holders that would sit on one or more of the cleats depending on how long they were. I could create anything from chisel racks to saw holders.

What I'm shooting for is flexibility in design, and the ability to reconfigure when I need to. I got the idea from a couple of places. I remember seeing a store shelving system years ago where they put in a wall of slotted wooden panels. They used metal pegs of varying lengths to hang displays or shelves from. It looked nice and was very flexible. I also saw a photo from a recent issue of Dwell that showed the interior of some woodworking shop and the wall of hand tools used by this person. A friend gave it to me, so I don't know the details of whose shop it was etc. They used a system of furring strips with horizontal tool holders screwed to these strips running vertically down the wall. It looked cool and easy to access the tools, but anytime you'd want to change things you'd be unscrewing and screwing in these horizontal holders.

So, yesterday afternoon I stopped by a local building supply place and picked up some 1x4 southern yellow pine. I found some nice pieces where the grain ran almost straight up and down between the two faces. Nice and stable and not cupped or warped at all.

Last evening was spent cutting to size, and then working to make the M&T joints for the frame. This is 3/4" stuff and so the joint turns into a wide and thin tenon. I was going to cut them as through tenons but I realized my tenon saw is not quite large enough to cut a 3.75" tenon cheek. I need a bigger tenon saw. :-) I ended up making the tenon smaller, not full depth, so I could cut it with my tenon saw.

I also tried cutting this mortise by hand. I still need work on this skill. I can get it to a certain depth, not quite half-way through, and then can't seem to figure out how to get more depth. Perhaps I get impatient, but most likely I just need more practice. I think I'm going to have to go with drilling the mortises with my brace and bit like I did when I made all the same-sized mortises for my tv table.

It was fun getting back in the shop, and I felt I needed this little refresher since I'm heading over to Roy's new school for a class this Sunday, and M&T joints in on the curriculum! It's also good to experiment to figure out if this is really the way I want to connect the frames together, or if perhaps a half-lap will be better. I still have some playing around to do. Yipee!

Friday, February 27, 2009

Thursday, February 12, 2009

Random Thought - Bed construction

I periodically think about adding a bed to my list of "things to build once I finish my bench" but I've never really like those giant bed bolts, and I'm not sure why.

I had a thought the other day about how to possibly make a bed that's still knock-down without using bed bolts. I wonder if you could fix the tenons from the long stretchers using the brass hinge bolts I used for my bench.

You would construct the headboard and footboard with pinned mortise and tenons so they're fixed. Then make the long m & t joints for the side stretchers and pin them with the brass hinge bolts. I wonder how that would stand up to use? I suspect if your tenon is long enough, the hinge bolt would be enough support to keep it from pulling out.

It's a though, a random thought.

AAAndrew

I had a thought the other day about how to possibly make a bed that's still knock-down without using bed bolts. I wonder if you could fix the tenons from the long stretchers using the brass hinge bolts I used for my bench.

You would construct the headboard and footboard with pinned mortise and tenons so they're fixed. Then make the long m & t joints for the side stretchers and pin them with the brass hinge bolts. I wonder how that would stand up to use? I suspect if your tenon is long enough, the hinge bolt would be enough support to keep it from pulling out.

It's a though, a random thought.

AAAndrew

Visited St. Roy's Shop

I cross posted this on a couple of forums (Old Tools, NC Woodworker) but wanted to keep a copy of it here for my own records.

I played hookey from work on Monday for a long lunch in the sunshine and

drove the 30 minutes down the road to Pittsboro, NC where Roy

Underhill is opening up a school for Galoot woodworking classes. I've

been hearing rumors and when I ran into him at the Woodworking in

America conference we spoke briefly about it. He was still waiting for

the benches and insurance to begin classes.

Well, he definitely has the benches! It looks all ready to go. It also

looks like a little slice of galoot heaven.

Now, you'll have to forgive the poor quality of photos, but I was

standing outside the windows looking in and taking pictures with my

iPhone on a sunny day.

That said...

Here's a view of the shop from the door.

There are ten benches, a spring pole lathe, a tredal wheel jigsaw and

a bunch of other stuff. Each bench has a carpenter's square lined up

along the corner, a small clamp, a bench hook and an assortment of

galootish tools underneath.

On the left side (facing in) is a saw sharpening bench with a backsaw

in the saw vise. (that giant plane is made of wood, including the

"iron")

Here's the left side again along with a bit of my finger. You can also

see the lathe on the right, and behind it the dark-colored pedal

jigsaw. Behind that is his little Roubo-ette bench.

Not sure what this is, but the window has plenty of odd bits and

pieces of things he's done on this show along with some whats-its and

a big old boring machine.

On the right side is a station with some sharpening things as well as

a couple of microscopes. Notice the picture of FDR up on the wall and

a poster from the WPA advising you to "Wear Your Goggles". You can

also see the reflection of another WPA poster that's in the front

window like they used to do.

Here's a picture of the benches on the right where you can see that

some have wooden planes as the tools you use.

On the left benches I saw some metal planes. It didn't seem like there

was a "wooden" side and the "metal" side, just that the front benches

reflected the diversity of viewpoints available. (nothing with tails)

The school in on the corner, and just around it is an essential

element for any woodworking school, the pub.

For more info this sign is on the door

It was a lot of fun peering into the windows. I can't imagine what it

will be like to actually take classes there. I'm psyched. :-)

I played hookey from work on Monday for a long lunch in the sunshine and

drove the 30 minutes down the road to Pittsboro, NC where Roy

Underhill is opening up a school for Galoot woodworking classes. I've

been hearing rumors and when I ran into him at the Woodworking in

America conference we spoke briefly about it. He was still waiting for

the benches and insurance to begin classes.

Well, he definitely has the benches! It looks all ready to go. It also

looks like a little slice of galoot heaven.

Now, you'll have to forgive the poor quality of photos, but I was

standing outside the windows looking in and taking pictures with my

iPhone on a sunny day.

That said...

Here's a view of the shop from the door.

There are ten benches, a spring pole lathe, a tredal wheel jigsaw and

a bunch of other stuff. Each bench has a carpenter's square lined up

along the corner, a small clamp, a bench hook and an assortment of

galootish tools underneath.

On the left side (facing in) is a saw sharpening bench with a backsaw

in the saw vise. (that giant plane is made of wood, including the

"iron")

Here's the left side again along with a bit of my finger. You can also

see the lathe on the right, and behind it the dark-colored pedal

jigsaw. Behind that is his little Roubo-ette bench.

Not sure what this is, but the window has plenty of odd bits and

pieces of things he's done on this show along with some whats-its and

a big old boring machine.

On the right side is a station with some sharpening things as well as

a couple of microscopes. Notice the picture of FDR up on the wall and

a poster from the WPA advising you to "Wear Your Goggles". You can

also see the reflection of another WPA poster that's in the front

window like they used to do.

Here's a picture of the benches on the right where you can see that

some have wooden planes as the tools you use.

On the left benches I saw some metal planes. It didn't seem like there

was a "wooden" side and the "metal" side, just that the front benches

reflected the diversity of viewpoints available. (nothing with tails)

The school in on the corner, and just around it is an essential

element for any woodworking school, the pub.

For more info this sign is on the door

It was a lot of fun peering into the windows. I can't imagine what it

will be like to actually take classes there. I'm psyched. :-)

Sunday, February 8, 2009

Roubu Bench - part 4: Figuring out the Wagon Vise

So, I've got the boards for the top all sorted out, numbered and aligned for grain direction. Now my job is to do any work to them that I want to do before I glue them up. Cutting a groove for the sliding deadman in the bottom of the first board is a whole lot easier in a single board then trying to do it by flipping and manhandling a 140 lb. top. Yes, the top should weight just about exactly 140 lbs. I weighted one of the 14 boards for the top and it came out to exactly 10.0 pounds on my bathroom scale.

The main problem I need to solve is the wagon vise. After looking at all kinds of tail vises, reading what Chris Schwarz and lots of others have written, I decided that I wanted to try and build this rather simple-looking sliding bench dog. That's the approach I'm taking is to look at it like I'm creating a bench dog that slides.

There's not a whole lot out there on wagon vises. Chris's book shows his retro-fit to his workbench and how he did it. I like the look, but I'd like to see if I can make something a little more integral to the bench itself than the slots screwed to the bottom of the bench.

I also had another major limitation. When I went to buy a screw for my wagon vise, all I could find locally was at the Woodcraft they sold a small veneer or cider press vise screw.

I chose this because I didn't think I needed a massive screw, it looked similar to what Chris had in his bench, and it was cheap and readily available. As I began to work through the problem of how to install this in the bench, I did do another search and figured out that there's a real gap in the bench screw market. We need a solid 1/2" diameter bench screw version of the normally massive 1" one you find all over the place. Even screws for shoulder vises were just too beefy. I saw a place in England selling one that seemed just what I wanted made in the Czech Republic, but it didn't seem to be sold on this side of the Atlantic and looked like too much trouble to get. I'd just make do with what I had.

The two primary problems, at this point, to be solved were: how to make the chop and attach it to the vise, and how to attach the chop to the bench so that it stays fairly stable and yet slides easily. You want a fairly low tolerances of slop, but there will always be some. The first question was made even more interesting in that the end pad of the vise screw did not have holes to fasten it to the chop, and not a whole lot of meat to drill the holes through. I was also concerned about just using screws to hold the pad to the chop, especially if I was able to stabilize the rest of the setup enough to be able to use the vise to pull as well as push, such as disassembling parts.

I began by actually trying to solve the second problem first. How would I attached the chop to the bench, and how to let it slide? Chris had installed runners under his bench and had a free floating chop running through the slot cut into the bench top. I wanted mine to be a bit more integral so I started down the road of a tab in a slot.

My first "brilliant idea" was to get a pre-made dovetailed drawer slide from Rockler and use that as the slide for the chop. I thought about mounting it underneath like Chris, or embedding it in the sides with the male part of the dovetail slide (the pin?) embedded in the chop. I ordered one and it was fine for a drawer, but it didn't seem tight enough or beefy enough.

I then thought of Occam's razor and decided that if I was going to have to cut a groove to embed the slide, why not just use a simple groove in the interior face of the slot, and tabs on the sides of the chop. Voile!

I played around with possibly making the tab a half-dovetail shape so that as the chop tried to move upwards with clamping pressure the chop would become wedged tighter in the triangular space above. BTW, I abandoned the idea of a sliding dovetail at this point for the sides as I thought of the wonderful fun I'd have cleaning chips and dust out of the lower parts of the groove. The bottom of the groove has to be flat for easy clean out.

I ended up going with the simplest solution that works, and no simpler: a simple square groove cut into the sides of the slot in the bench, and tabs on the chop riding in that slot. One problem decided. Sort of.

OK, that whole process took a bit longer than it did to describe it. I actually came to the conclusion over the long process of building the chop with the general idea of tab and groove construction. I actually got to the point of marking out the half-dovetail-shaped tabs on the chop when I tried to actually cut the groove in a test piece of wood. It was significantly harder to do than a straight groove without a good stair saw or equivalent, especially as I wanted this to be a stopped groove. And I wasn't going to stop my bench building in order to finally make the stair saw I've been wanting to make for a while.

So now I had to figure out how to make the chop. The easier thing would be to take a couple of hunks of wood that fit the size of the slot in the bench. OK, how big will the slot be? My original drawings showed it to be the width of one of my boards, 1 3/4" wide. As I looked more closely at the screw, the guide plate, or whatever it's called that holds the screw up by the handle, is just over 1" wide at its widest. That would not leave much room for the screws on either side. I decided to double it and make it beefier. So, my slot is now 3.5" wide.

The next problem to think through was how to make the chop. (wasn't that the problem above? That just illustrates the constant process that in order to solve one problem you've got to solve three others) So, I wanted to think about grain orientation and stress on the tabs. It's much harder to snap off a piece of wood across the grain than it is going with the grain, so it made sense, at least to me, to have the grain orientation of the chop perpendicular to the orientation of the bench top. This way, the upward or downward pressure on the chop would be trying to snap off the tabs across the grain. It also allowed me to laminate the chop in such a way as to capture the pad of the vise within the wood to make a solid connection for either pulling or pushing.

Let me talk about the laminating for a second. I figured there were only a few ways of affixing this pad at the end of the vise screw to a wooden chop: drill holes in it to use screws or small bolts, or encase the pad in the wood and count on the strength of the glue on a large face-to-face glue joint to hold it in. I went with the second approach. I figured if it didn't work, then I could still try the first.

The chop is in three parts. The first part is just a piece of 4/4 maple that will eventually hold the hole for the bench dog. The second, middle piece has a shallow square cut out for the pad so that the pad sits below the level of the face that abuts the third part. The third part is the most complex part in that it must have a hole for the collar that captures the screw itself, and, since I wanted the ability to take the screw out, I needed a slot to access the screw at the bottom of the pad that held the screw into the collar. Perhaps we need some pictures.

I roughly cut to shape the three parts, marked out my final cuts and then glued them together just in the places where I'd eventually cut them out, so just at the corners. This allowed me to cut them all at the same time. And man, do I need a good carcass saw.

Here's the second part with the small square being cut out

Here's a picture of it all glued up. I left it long on the bottom since I was using some scrap 5" wide boards from the legs. After glue up I cut them to the width of the top. You can still see the layout lines on the tabs for my original idea of a half-dovetail shape.

Here's how the whole thing fits together

In the last picture you can see a couple of the reminders of just how painful the whole process was to create the chops. You'd think this was a fairly straight-forward piece of woodworking, and you'd be right, but it's where the piecemeal nature of my shop time can be deadly. I ended up cutting four sets of the chop pieces before I got it right. The end of the screw is sitting on a couple of the victims of my inattention.

The first set I cut out and realized the tabs were too small. The second set I glue up together before hitting myself over my head with my persuader because I hadn't cut any slots or holes or squares and encased the pad. The third set I mis-measured and the dimension to the outside the tabs was equal to the inside dimension of the slot, so too narrow. ("Measure 10 times, cut once. Measure 10 times, cut once...") I even cut two pieces of a fifth set to the dovetail shape before abandoning that idea, so it was almost five sets. Each mistake is almost directly tied to the fact that I had no real plan for the chop and since I was coming into the shop for only a couple of hours a week, I was always rushed and had to catch up to what I had been thinking a week before. Almost. I can also just be plain stupid at times.

Anyway, I have the chop, and now needed to test it out.

I'm all about doing this whole thing at least twice to learn the first time so that when I do it for real I have that much more of a chance of doing it right. So, I took a couple of off-cuts from the lumber for the top and set up a small model of that part of the bench with the slot, and marked out and started to cut the groove.

The groove for the tabs to ride in is approximately 1" wide, at least 1/2" deep and 10" long. I've thought about doing them as stopped only on one end, stopped grooves on both ends, or stopped grooves with The Schwarz's technique of drilling a hole in each end and using a moving fillister to cut them. Unfortunately, I don't have a moving fillister beyond my combo plane, and I didn't relish trying to use that to cut such a large groove. So I tried the chisel technique I learned at Woodworking in America.

It worked, and I now have a full-sized, stopped groove and it worked really well, but it is a lot like work, especially with the quality of my 1" bench chisels. I recently found a galoot who is selling me a 1/2" pigsticker mortise chisel which I hope to try out and use on the final cut. It should make much shorter work of the final groove and can help with cutting the other groove I need to cut for the sliding deadman. That groove will be much longer, closer to 36".

Well. We're finally caught up to where I am on the bench. It's been an adventure so far, and I'm sure I'll have plenty more to learn as I go along. And after all, that's kind of the whole reason to build my own bench, for the experience of it.

See you next time,

AAAndrew

The main problem I need to solve is the wagon vise. After looking at all kinds of tail vises, reading what Chris Schwarz and lots of others have written, I decided that I wanted to try and build this rather simple-looking sliding bench dog. That's the approach I'm taking is to look at it like I'm creating a bench dog that slides.

There's not a whole lot out there on wagon vises. Chris's book shows his retro-fit to his workbench and how he did it. I like the look, but I'd like to see if I can make something a little more integral to the bench itself than the slots screwed to the bottom of the bench.

I also had another major limitation. When I went to buy a screw for my wagon vise, all I could find locally was at the Woodcraft they sold a small veneer or cider press vise screw.

I chose this because I didn't think I needed a massive screw, it looked similar to what Chris had in his bench, and it was cheap and readily available. As I began to work through the problem of how to install this in the bench, I did do another search and figured out that there's a real gap in the bench screw market. We need a solid 1/2" diameter bench screw version of the normally massive 1" one you find all over the place. Even screws for shoulder vises were just too beefy. I saw a place in England selling one that seemed just what I wanted made in the Czech Republic, but it didn't seem to be sold on this side of the Atlantic and looked like too much trouble to get. I'd just make do with what I had.

The two primary problems, at this point, to be solved were: how to make the chop and attach it to the vise, and how to attach the chop to the bench so that it stays fairly stable and yet slides easily. You want a fairly low tolerances of slop, but there will always be some. The first question was made even more interesting in that the end pad of the vise screw did not have holes to fasten it to the chop, and not a whole lot of meat to drill the holes through. I was also concerned about just using screws to hold the pad to the chop, especially if I was able to stabilize the rest of the setup enough to be able to use the vise to pull as well as push, such as disassembling parts.

I began by actually trying to solve the second problem first. How would I attached the chop to the bench, and how to let it slide? Chris had installed runners under his bench and had a free floating chop running through the slot cut into the bench top. I wanted mine to be a bit more integral so I started down the road of a tab in a slot.

My first "brilliant idea" was to get a pre-made dovetailed drawer slide from Rockler and use that as the slide for the chop. I thought about mounting it underneath like Chris, or embedding it in the sides with the male part of the dovetail slide (the pin?) embedded in the chop. I ordered one and it was fine for a drawer, but it didn't seem tight enough or beefy enough.

I then thought of Occam's razor and decided that if I was going to have to cut a groove to embed the slide, why not just use a simple groove in the interior face of the slot, and tabs on the sides of the chop. Voile!

I played around with possibly making the tab a half-dovetail shape so that as the chop tried to move upwards with clamping pressure the chop would become wedged tighter in the triangular space above. BTW, I abandoned the idea of a sliding dovetail at this point for the sides as I thought of the wonderful fun I'd have cleaning chips and dust out of the lower parts of the groove. The bottom of the groove has to be flat for easy clean out.

I ended up going with the simplest solution that works, and no simpler: a simple square groove cut into the sides of the slot in the bench, and tabs on the chop riding in that slot. One problem decided. Sort of.

OK, that whole process took a bit longer than it did to describe it. I actually came to the conclusion over the long process of building the chop with the general idea of tab and groove construction. I actually got to the point of marking out the half-dovetail-shaped tabs on the chop when I tried to actually cut the groove in a test piece of wood. It was significantly harder to do than a straight groove without a good stair saw or equivalent, especially as I wanted this to be a stopped groove. And I wasn't going to stop my bench building in order to finally make the stair saw I've been wanting to make for a while.

So now I had to figure out how to make the chop. The easier thing would be to take a couple of hunks of wood that fit the size of the slot in the bench. OK, how big will the slot be? My original drawings showed it to be the width of one of my boards, 1 3/4" wide. As I looked more closely at the screw, the guide plate, or whatever it's called that holds the screw up by the handle, is just over 1" wide at its widest. That would not leave much room for the screws on either side. I decided to double it and make it beefier. So, my slot is now 3.5" wide.

The next problem to think through was how to make the chop. (wasn't that the problem above? That just illustrates the constant process that in order to solve one problem you've got to solve three others) So, I wanted to think about grain orientation and stress on the tabs. It's much harder to snap off a piece of wood across the grain than it is going with the grain, so it made sense, at least to me, to have the grain orientation of the chop perpendicular to the orientation of the bench top. This way, the upward or downward pressure on the chop would be trying to snap off the tabs across the grain. It also allowed me to laminate the chop in such a way as to capture the pad of the vise within the wood to make a solid connection for either pulling or pushing.

Let me talk about the laminating for a second. I figured there were only a few ways of affixing this pad at the end of the vise screw to a wooden chop: drill holes in it to use screws or small bolts, or encase the pad in the wood and count on the strength of the glue on a large face-to-face glue joint to hold it in. I went with the second approach. I figured if it didn't work, then I could still try the first.

The chop is in three parts. The first part is just a piece of 4/4 maple that will eventually hold the hole for the bench dog. The second, middle piece has a shallow square cut out for the pad so that the pad sits below the level of the face that abuts the third part. The third part is the most complex part in that it must have a hole for the collar that captures the screw itself, and, since I wanted the ability to take the screw out, I needed a slot to access the screw at the bottom of the pad that held the screw into the collar. Perhaps we need some pictures.

I roughly cut to shape the three parts, marked out my final cuts and then glued them together just in the places where I'd eventually cut them out, so just at the corners. This allowed me to cut them all at the same time. And man, do I need a good carcass saw.

Here's the second part with the small square being cut out

Here's a picture of it all glued up. I left it long on the bottom since I was using some scrap 5" wide boards from the legs. After glue up I cut them to the width of the top. You can still see the layout lines on the tabs for my original idea of a half-dovetail shape.

Here's how the whole thing fits together

In the last picture you can see a couple of the reminders of just how painful the whole process was to create the chops. You'd think this was a fairly straight-forward piece of woodworking, and you'd be right, but it's where the piecemeal nature of my shop time can be deadly. I ended up cutting four sets of the chop pieces before I got it right. The end of the screw is sitting on a couple of the victims of my inattention.

The first set I cut out and realized the tabs were too small. The second set I glue up together before hitting myself over my head with my persuader because I hadn't cut any slots or holes or squares and encased the pad. The third set I mis-measured and the dimension to the outside the tabs was equal to the inside dimension of the slot, so too narrow. ("Measure 10 times, cut once. Measure 10 times, cut once...") I even cut two pieces of a fifth set to the dovetail shape before abandoning that idea, so it was almost five sets. Each mistake is almost directly tied to the fact that I had no real plan for the chop and since I was coming into the shop for only a couple of hours a week, I was always rushed and had to catch up to what I had been thinking a week before. Almost. I can also just be plain stupid at times.

Anyway, I have the chop, and now needed to test it out.

I'm all about doing this whole thing at least twice to learn the first time so that when I do it for real I have that much more of a chance of doing it right. So, I took a couple of off-cuts from the lumber for the top and set up a small model of that part of the bench with the slot, and marked out and started to cut the groove.

The groove for the tabs to ride in is approximately 1" wide, at least 1/2" deep and 10" long. I've thought about doing them as stopped only on one end, stopped grooves on both ends, or stopped grooves with The Schwarz's technique of drilling a hole in each end and using a moving fillister to cut them. Unfortunately, I don't have a moving fillister beyond my combo plane, and I didn't relish trying to use that to cut such a large groove. So I tried the chisel technique I learned at Woodworking in America.

It worked, and I now have a full-sized, stopped groove and it worked really well, but it is a lot like work, especially with the quality of my 1" bench chisels. I recently found a galoot who is selling me a 1/2" pigsticker mortise chisel which I hope to try out and use on the final cut. It should make much shorter work of the final groove and can help with cutting the other groove I need to cut for the sliding deadman. That groove will be much longer, closer to 36".

Well. We're finally caught up to where I am on the bench. It's been an adventure so far, and I'm sure I'll have plenty more to learn as I go along. And after all, that's kind of the whole reason to build my own bench, for the experience of it.

See you next time,

AAAndrew

Friday, February 6, 2009

While I'm at it

Here's another of my favorite photos from Woodworking in America

Frank Klausz and Roy Underhill demonstrating some alcohol-powered woodworking.

I've also uploaded one of my videos from the conference of Frank Klausz demonstrating how to cut a mortise by hand.

I'll get back to my bench next time.

AAAndrew

Frank Klausz and Roy Underhill demonstrating some alcohol-powered woodworking.

I've also uploaded one of my videos from the conference of Frank Klausz demonstrating how to cut a mortise by hand.

I'll get back to my bench next time.

AAAndrew

Thursday, February 5, 2009

Interlude

Inspired by a thread on another blog I ran across, here's a picture of me with a famous person, and a famous bench.

It's me with Chris Schwarz and his famous Roubo bench that started it all for me, and many others.

It was taken at the Woodworking in America Conference. And you're really getting a three-fer as that's Mike Wenzloff of Wenzloff and Sons Saw Makers in the background. I told you it was an amazing conference.

AAAndrew

It's me with Chris Schwarz and his famous Roubo bench that started it all for me, and many others.

It was taken at the Woodworking in America Conference. And you're really getting a three-fer as that's Mike Wenzloff of Wenzloff and Sons Saw Makers in the background. I told you it was an amazing conference.

AAAndrew

Wednesday, February 4, 2009

Roubo Bench - part 3: Planning the top

Finishing the base was a major milestone and I needed to stop and take stock of where I was and how to proceed going forward. The next obvious step was to make the top, attach it, then move on to the leg vise and sliding deadman, then drill the holes and Robert shall be your mother's brother. But I'm learning, and knew that making the top is going to require a fair bit of planning before I can get to the planing.

When I was cutting the wood to length for the legs, I had also played around and cut a couple of pieces for the top to length as well. I now realized how stupid that was.

One of the lessons I've learned in this project is to not cut to final length until you have to. You can have all the drawings you want with precise a measurements as your tool will give you, but, unless you’re using a CNC machine to cut your parts, you've got to, in the end, use the measurements of the material and the piece to figure out how big or small to make it. The final measurements will become obvious as you build it.

I actually already knew this lesson but had forgotten it. I learned it when building the tv table. For that project I had never used a drawing at all, and almost never used a ruler. Instead, I had used a rough estimate of height marked out on a stick, subtracted the approximate thickness of my top, then built my first leg to that length. I used that leg to make the other legs, then used the size of the top, derived from the size of the tv going on top of it, to determine the length of the side and front. None of this was measured with a tape measure or ruler. I just used the items themselves. I ended up making a story stick, but then blew that lesson by losing it. [sigh]

I should have re-learned that lesson when building the bookcase when I screwed up the last shelf by cutting it too short. But I didn't realize what I had learned. (or re-learned)

So, now I had to begin with the boards for the top. I cleared my bench top (a weekend in itself) and began laying out which boards went where. I then tested each board by planing it to confirm I was reading the grain right and aligned them so that they all were oriented the same way. I made it so that if I planed them from right to left, my natural direction for planing, there should be no tearout (or as little as possible).

I also put the boards in my initial order and marked them 1-14.

I have just one spare board for the top, so my margin of error is shrinking. I still have to determine, finally, where the boards I’ve already cut to length will go. I have a couple I cut to very short length to be the boards where the planing stop will go and the boards where the wagon vise will sit. But I'm beginning to think that I want final-length boards (which is 60") to be at the top and bottom of my bench. my thinking is that then, when I go to cut off the ends, which I'm planning on doing by kneeling on top of the bench and cutting with a handsaw, I have a guide against which to rest the saw at the beginning of the cut for both sides.

So, I'm imagining it as me up on the top, I have a line drawn from the end of the last board all the way down to the end of the first board with the rest of the boards sticking past the line to some degree. Where I start the cut will be on a second board (second from front, or second from back depending on which side I'm cutting). My saw will rest against the end of the first board (first in back, first in front, depending, etc...) and use that to help me get the cut going straight from the start.

To make this work, I'm going to have to do a few things really right. I'm going to have to get the first and last board lined up perfectly, which means I'm probably going to have to glue the last board all by itself to be able to take the care this will entail.

I'm also going to have to line up, at least on the right side of the bench, the boards for the wagon vise just perfectly too. Effectively, I'll have to line up, at least on the right side, boards 1 (front board), 2-5 (wagon vise) and then 14. The rest I want to leave an inch or so proud of the line and then cut 13-6 to final length. That makes 14" to cross cut as close as I can get to the line. I don't think that's too daunting. I'll then touch up the end grain with some alcohol and my block plane. And if I do that to the ends of the first and last board individually, then I won't have to worry about coming in from both sides, or popping out the ends as the plane leaves the board.

What this means is that I'll have to cut the rest of the boards to about 2-3" too long in order to have the margin for error I'm looking for. I could leave them really long, but I'm going to need some of that length for the wagon vise end. (I’ll explain next post)

But before I do that, there's some more prep work and experimenting I'm going to need to do, namely figure out my wagon vise, and then cut the groove in the front board for the deadman to ride in. This has to all be figured out before I put glue to a single board.

This preparation is essential. It's like cooking Chinese, you have to have all the chopping and measuring done ahead of time, because once you start, it's difficult to stop the process and go back to do something over, or prepare each ingredient only as needed. Once I start gluing up the top, I won't have the work surface to do anything big like figure out the wagon vise, or cut the massive groove I'm going to need for the deadman. Figure this out now, make the prep cuts needed that will be next to impossible with my tools once I glue up, and then git 'er done.

Next I'll talk about all the work I've been doing to figure out how I'm going to build the wagon vise. We're approaching my actual place in the process, so once I catch up, the posts should be a bit shorter, more detailed and perhaps a bit sporadic.

AAAndrew

When I was cutting the wood to length for the legs, I had also played around and cut a couple of pieces for the top to length as well. I now realized how stupid that was.

One of the lessons I've learned in this project is to not cut to final length until you have to. You can have all the drawings you want with precise a measurements as your tool will give you, but, unless you’re using a CNC machine to cut your parts, you've got to, in the end, use the measurements of the material and the piece to figure out how big or small to make it. The final measurements will become obvious as you build it.

I actually already knew this lesson but had forgotten it. I learned it when building the tv table. For that project I had never used a drawing at all, and almost never used a ruler. Instead, I had used a rough estimate of height marked out on a stick, subtracted the approximate thickness of my top, then built my first leg to that length. I used that leg to make the other legs, then used the size of the top, derived from the size of the tv going on top of it, to determine the length of the side and front. None of this was measured with a tape measure or ruler. I just used the items themselves. I ended up making a story stick, but then blew that lesson by losing it. [sigh]

I should have re-learned that lesson when building the bookcase when I screwed up the last shelf by cutting it too short. But I didn't realize what I had learned. (or re-learned)

So, now I had to begin with the boards for the top. I cleared my bench top (a weekend in itself) and began laying out which boards went where. I then tested each board by planing it to confirm I was reading the grain right and aligned them so that they all were oriented the same way. I made it so that if I planed them from right to left, my natural direction for planing, there should be no tearout (or as little as possible).

I also put the boards in my initial order and marked them 1-14.

I have just one spare board for the top, so my margin of error is shrinking. I still have to determine, finally, where the boards I’ve already cut to length will go. I have a couple I cut to very short length to be the boards where the planing stop will go and the boards where the wagon vise will sit. But I'm beginning to think that I want final-length boards (which is 60") to be at the top and bottom of my bench. my thinking is that then, when I go to cut off the ends, which I'm planning on doing by kneeling on top of the bench and cutting with a handsaw, I have a guide against which to rest the saw at the beginning of the cut for both sides.

So, I'm imagining it as me up on the top, I have a line drawn from the end of the last board all the way down to the end of the first board with the rest of the boards sticking past the line to some degree. Where I start the cut will be on a second board (second from front, or second from back depending on which side I'm cutting). My saw will rest against the end of the first board (first in back, first in front, depending, etc...) and use that to help me get the cut going straight from the start.

To make this work, I'm going to have to do a few things really right. I'm going to have to get the first and last board lined up perfectly, which means I'm probably going to have to glue the last board all by itself to be able to take the care this will entail.

I'm also going to have to line up, at least on the right side of the bench, the boards for the wagon vise just perfectly too. Effectively, I'll have to line up, at least on the right side, boards 1 (front board), 2-5 (wagon vise) and then 14. The rest I want to leave an inch or so proud of the line and then cut 13-6 to final length. That makes 14" to cross cut as close as I can get to the line. I don't think that's too daunting. I'll then touch up the end grain with some alcohol and my block plane. And if I do that to the ends of the first and last board individually, then I won't have to worry about coming in from both sides, or popping out the ends as the plane leaves the board.

What this means is that I'll have to cut the rest of the boards to about 2-3" too long in order to have the margin for error I'm looking for. I could leave them really long, but I'm going to need some of that length for the wagon vise end. (I’ll explain next post)

But before I do that, there's some more prep work and experimenting I'm going to need to do, namely figure out my wagon vise, and then cut the groove in the front board for the deadman to ride in. This has to all be figured out before I put glue to a single board.

This preparation is essential. It's like cooking Chinese, you have to have all the chopping and measuring done ahead of time, because once you start, it's difficult to stop the process and go back to do something over, or prepare each ingredient only as needed. Once I start gluing up the top, I won't have the work surface to do anything big like figure out the wagon vise, or cut the massive groove I'm going to need for the deadman. Figure this out now, make the prep cuts needed that will be next to impossible with my tools once I glue up, and then git 'er done.

Next I'll talk about all the work I've been doing to figure out how I'm going to build the wagon vise. We're approaching my actual place in the process, so once I catch up, the posts should be a bit shorter, more detailed and perhaps a bit sporadic.

AAAndrew

Tuesday, February 3, 2009

Roubo Bench - part 2: The Base

In this episode, I describe how I built the base. I decided to begin with the base for a very good reason, unfortunately I can't quite remember what it was, but it was good, I assure you.

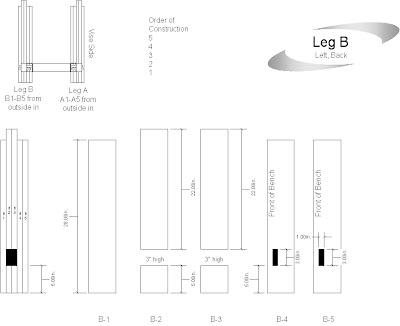

Here is the page from my Visio plans for the base.

I wanted to keep the leg dimensions the same, each is made of 5 4/4 boards, each 5" wide. Glued up together they make a true 5x5 leg. I laminated them allowing for the open mortise to go through the leg for the long stretchers. This saved me the trouble of cutting a 2"x3"x5" deep mortise through the leg. That was a lot of trouble saved.

As you can see from the plan, I toyed with making the long stretchers longer and then possibly putting wedged tusks through because from the beginning I wanted to make the bench so I could knock it down for moving. I ended up trying something different to the same effect.

I began by cutting all the leg parts to size.

I determined outside faces and began gluing. At this point I still hadn't learned the very basic lesson of ensuring all boards grain is going in the same direction. Fortunately, it's not as important on the legs. If there's a little tear-out, not such a huge deal.

The glue-up was a little more tricky than I anticipated. For one thing, with only short times in the shop, less than two hours a week, you really can get much glued up in that time. It also didn't help that right after I got the first leg finished I ended up having to have surgery, twice, and then radiation treatment all covering from March through June. When you can't even lift the weight of one leg, it's not so easy to make them. I managed to get some parts glued up and get some of the legs finished.

Once I got the legs put together I then finished them a bit, smoothing down some of the roughness, and beveling the bottom edges to avoid tearing out chunks as you drag it across the floor.

Next it was time to make the stretchers. I began with the short stretchers. I built them to the plan. Then I bothered measuring the wood. Oops. The boards in my drawn plan were 8/4 (2-inches) thick. The boards I ended up getting were 7/4 (1.75" thick). This kind of threw off the measurements of my top. I decided to go with 14 boards wide, thus giving me 24.5" exactly. But I had drawn my design for 12 2" boards thus yielding a 24" wide top. I had just built stretchers just .5" too short. Back to the lumber pile. This is why you buy more lumber than you need!

Because of this blunder, one of my long stretchers has two pieces butted up together to make the inside section of the laminate. (BS1 on the diagram)

It was at this point that I came up with the idea of how I was going to make this a knock-down bench. Instead of through tenons with wedges, I was still going to make them through tenons, but I was going to pin them. I thought about wooden pins that I could then drill out should I wish to move, but then had an idea.

I'm not sure where I got the idea from, whether I came up with it totally on my own or something gave me the idea but I thought about the large pins that hold door hinges together. They're about 1/4" in diameter, 4" long and have a head to give you some leverage when pulling them out. I mused on this idea all during the even slower period of intense end-of-season gardening that cuts into my already meager shop time as I help my wife get the beds ready for the winter.

I went to the Woodworking in America conference in November and absolutely loved it. While there I got to meet Chris Schwarz (and many others) and see the original bench he had built in the book. I ran the idea of the brass pins by him and others and while the reception was generally "sure, I guess you could do that, but not sure why" I got the impression it was something just not thought of before. I wasn't encouraged, nor was I discouraged. But seeing the original bench was very inspirational to get mine done!

I finished the stretchers and began to put the base together. First I began with the (new) short stretchers.

I cut my own pegs from some tough, straight-grained pine I had. I first tested it for shear strength by putting one peg into my vise and whacking it with a mallet. I have two mallets, one round carving mallet that I use for everyday whacking, and then the one you see in the photo, my "Persuader" that I bought at an antique store for $20. The store is one of those that get "antiques" by the container load from Britain. The head is about 2-pounds and very hard. It's wonderfully persuasive, and when it took some really hard whacks with the persuader to break the pin, I was satisfied.

What looks like a crack along the pins is actually just uneven glue-up. This was planed down smooth later.

The brace and bit in the picture represent the wonderful time I had cutting the 1"x3" by 2" deep mortises into the maple legs. The mortises go all the way through to the long stretcher mortise, which helped for figuring out depth, but man, that's a huge mortise to cut out. Taking down the sides to be smooth and straight proved to be a real challenge at times. At least one is not terribly straight and has a small gap where the wall is undercut at the bottom. I could wedge it, but I figured after pinning and once it's all together with the top on, the stress on that particular joint will not be such that the gap will compromise any strength.

This was a really exciting moment. For the first time, this pile of wood began to look like something. It was fun to have a leg. It was more fun to have four legs. This was now even better.

The next step was to begin and fit the huge tenons of the long stretchers into the massive mortises. I had to fare the mortises and sometimes the tenons to get them to fit. The mortises had been created by just gluing shorter pieces and I had used patterns of the tenons to help keep spacing, but it's never perfect.

Then there was the fateful day when I was ready and used my persuader and several sacrificial blocks to protect the ends of the tenons to pound these great suckers into the mortises. Getting one end together was harder than getting the other. Once I had one end on the floor with two long stretchers sticking out, I put the other end on top and saw more evidence (as if I needed it) that wood is a living material. What you couldn't see with casual inspection became obvious at this point, that one of the stretchers had a slight amount of twist to it.

This is where the mass of the whole thing comes into play. I just torqued the base around to get the tenon started, then used the mass of the end piece to help drive the whole thing down onto the tenons. It was much easier with the weight of the two legs helping me.

I now had the whole base put together.

Now that was a moment to celebrate. It is so massive and tightly put together that it is just not coming apart. The mass also overcame any issues with not quite even bottoms on some of the legs. The base does not rock or wobble even a hair's breadth. It is as solid as I could wish it.

So, despite feeling like I didn't really need them, I still wanted to experiment with the brass pins. I justified it by being concerned that racking of the base from planing might begin to work the tenons loose. When looked at dispassionately, I think the odds of that are pretty darned low considering the size of the joints, but we all have our caprices.

I obviously wanted the heads of the pins to sit below the level of the wooden leg to keep any metal off the surface of my bench, even the leg surface. I first marked out where the pins would go and drilled the countersink hole for the head of the pin with some of my wonderful center bits. I picked up a set of these some years ago and every time I use them I wonder why I don't use them more. They work so well.

You can see this picture was taken on the vise leg. The notch in the leg will be where the parallel guide will go. I cut out this notch on each individual board before glue up since cutting it in a 5" leg with a handsaw seemed to be much more fraught with peril than doing it on five 1" boards. And I want as little peril as I can get.

I then cut the ramp that will allow me access into the hole to pry up the head of the hinge pin. I had experimented with this whole setup before starting this on my bench, and I found out a couple of things. One of which was that cutting this ramp with a mortise chisel was really very easy, with a bench chisel, not quite as much. I just used the size of the mortise chisel to determine the ramp size since it was sufficient for the screwdriver I already had marked out as my prying tool.

I drilled the holes for the pin itself. I found in my experiments (I'm big on experimenting before doing anything terribly new, and that has paid off tremendously) that my Jennings bit made a hole that was too perfect and the fit was so tight that it really made it hard to get the pin out. My Irwin bit, on the other hand made a hole just perfect. There was some bite but I could also easily get the pin out.

The tenon in this picture looks worse than it is. That is not a gap you see, but actually the long stretcher is a fraction of an inch proud of the leg.

And voila, using a wooden "nail set" I drove home the pins with my persuader (overkill, but it's so much fun to use) and I have an amazingly stable and exciting (I know, I have a problem) bench base.

It was so satisfying to get to this point that I'm afraid I could easily develop "a bench problem" as Chris Schwarz talks about. And I haven't even built the top yet.

The next steps are figuring out some issues around the wagon vise and getting ready to make the top. But that's for next time.

AAAndrew

Here is the page from my Visio plans for the base.

|

| F |

I wanted to keep the leg dimensions the same, each is made of 5 4/4 boards, each 5" wide. Glued up together they make a true 5x5 leg. I laminated them allowing for the open mortise to go through the leg for the long stretchers. This saved me the trouble of cutting a 2"x3"x5" deep mortise through the leg. That was a lot of trouble saved.

As you can see from the plan, I toyed with making the long stretchers longer and then possibly putting wedged tusks through because from the beginning I wanted to make the bench so I could knock it down for moving. I ended up trying something different to the same effect.

I began by cutting all the leg parts to size.

|

I determined outside faces and began gluing. At this point I still hadn't learned the very basic lesson of ensuring all boards grain is going in the same direction. Fortunately, it's not as important on the legs. If there's a little tear-out, not such a huge deal.

The glue-up was a little more tricky than I anticipated. For one thing, with only short times in the shop, less than two hours a week, you really can get much glued up in that time. It also didn't help that right after I got the first leg finished I ended up having to have surgery, twice, and then radiation treatment all covering from March through June. When you can't even lift the weight of one leg, it's not so easy to make them. I managed to get some parts glued up and get some of the legs finished.

Once I got the legs put together I then finished them a bit, smoothing down some of the roughness, and beveling the bottom edges to avoid tearing out chunks as you drag it across the floor.

Next it was time to make the stretchers. I began with the short stretchers. I built them to the plan. Then I bothered measuring the wood. Oops. The boards in my drawn plan were 8/4 (2-inches) thick. The boards I ended up getting were 7/4 (1.75" thick). This kind of threw off the measurements of my top. I decided to go with 14 boards wide, thus giving me 24.5" exactly. But I had drawn my design for 12 2" boards thus yielding a 24" wide top. I had just built stretchers just .5" too short. Back to the lumber pile. This is why you buy more lumber than you need!

Because of this blunder, one of my long stretchers has two pieces butted up together to make the inside section of the laminate. (BS1 on the diagram)

|

It was at this point that I came up with the idea of how I was going to make this a knock-down bench. Instead of through tenons with wedges, I was still going to make them through tenons, but I was going to pin them. I thought about wooden pins that I could then drill out should I wish to move, but then had an idea.

I'm not sure where I got the idea from, whether I came up with it totally on my own or something gave me the idea but I thought about the large pins that hold door hinges together. They're about 1/4" in diameter, 4" long and have a head to give you some leverage when pulling them out. I mused on this idea all during the even slower period of intense end-of-season gardening that cuts into my already meager shop time as I help my wife get the beds ready for the winter.

I went to the Woodworking in America conference in November and absolutely loved it. While there I got to meet Chris Schwarz (and many others) and see the original bench he had built in the book. I ran the idea of the brass pins by him and others and while the reception was generally "sure, I guess you could do that, but not sure why" I got the impression it was something just not thought of before. I wasn't encouraged, nor was I discouraged. But seeing the original bench was very inspirational to get mine done!

I finished the stretchers and began to put the base together. First I began with the (new) short stretchers.

I cut my own pegs from some tough, straight-grained pine I had. I first tested it for shear strength by putting one peg into my vise and whacking it with a mallet. I have two mallets, one round carving mallet that I use for everyday whacking, and then the one you see in the photo, my "Persuader" that I bought at an antique store for $20. The store is one of those that get "antiques" by the container load from Britain. The head is about 2-pounds and very hard. It's wonderfully persuasive, and when it took some really hard whacks with the persuader to break the pin, I was satisfied.

What looks like a crack along the pins is actually just uneven glue-up. This was planed down smooth later.

The brace and bit in the picture represent the wonderful time I had cutting the 1"x3" by 2" deep mortises into the maple legs. The mortises go all the way through to the long stretcher mortise, which helped for figuring out depth, but man, that's a huge mortise to cut out. Taking down the sides to be smooth and straight proved to be a real challenge at times. At least one is not terribly straight and has a small gap where the wall is undercut at the bottom. I could wedge it, but I figured after pinning and once it's all together with the top on, the stress on that particular joint will not be such that the gap will compromise any strength.

This was a really exciting moment. For the first time, this pile of wood began to look like something. It was fun to have a leg. It was more fun to have four legs. This was now even better.

The next step was to begin and fit the huge tenons of the long stretchers into the massive mortises. I had to fare the mortises and sometimes the tenons to get them to fit. The mortises had been created by just gluing shorter pieces and I had used patterns of the tenons to help keep spacing, but it's never perfect.

Then there was the fateful day when I was ready and used my persuader and several sacrificial blocks to protect the ends of the tenons to pound these great suckers into the mortises. Getting one end together was harder than getting the other. Once I had one end on the floor with two long stretchers sticking out, I put the other end on top and saw more evidence (as if I needed it) that wood is a living material. What you couldn't see with casual inspection became obvious at this point, that one of the stretchers had a slight amount of twist to it.

This is where the mass of the whole thing comes into play. I just torqued the base around to get the tenon started, then used the mass of the end piece to help drive the whole thing down onto the tenons. It was much easier with the weight of the two legs helping me.

I now had the whole base put together.

Now that was a moment to celebrate. It is so massive and tightly put together that it is just not coming apart. The mass also overcame any issues with not quite even bottoms on some of the legs. The base does not rock or wobble even a hair's breadth. It is as solid as I could wish it.

So, despite feeling like I didn't really need them, I still wanted to experiment with the brass pins. I justified it by being concerned that racking of the base from planing might begin to work the tenons loose. When looked at dispassionately, I think the odds of that are pretty darned low considering the size of the joints, but we all have our caprices.

I obviously wanted the heads of the pins to sit below the level of the wooden leg to keep any metal off the surface of my bench, even the leg surface. I first marked out where the pins would go and drilled the countersink hole for the head of the pin with some of my wonderful center bits. I picked up a set of these some years ago and every time I use them I wonder why I don't use them more. They work so well.

You can see this picture was taken on the vise leg. The notch in the leg will be where the parallel guide will go. I cut out this notch on each individual board before glue up since cutting it in a 5" leg with a handsaw seemed to be much more fraught with peril than doing it on five 1" boards. And I want as little peril as I can get.

I then cut the ramp that will allow me access into the hole to pry up the head of the hinge pin. I had experimented with this whole setup before starting this on my bench, and I found out a couple of things. One of which was that cutting this ramp with a mortise chisel was really very easy, with a bench chisel, not quite as much. I just used the size of the mortise chisel to determine the ramp size since it was sufficient for the screwdriver I already had marked out as my prying tool.

I drilled the holes for the pin itself. I found in my experiments (I'm big on experimenting before doing anything terribly new, and that has paid off tremendously) that my Jennings bit made a hole that was too perfect and the fit was so tight that it really made it hard to get the pin out. My Irwin bit, on the other hand made a hole just perfect. There was some bite but I could also easily get the pin out.

The tenon in this picture looks worse than it is. That is not a gap you see, but actually the long stretcher is a fraction of an inch proud of the leg.

And voila, using a wooden "nail set" I drove home the pins with my persuader (overkill, but it's so much fun to use) and I have an amazingly stable and exciting (I know, I have a problem) bench base.

It was so satisfying to get to this point that I'm afraid I could easily develop "a bench problem" as Chris Schwarz talks about. And I haven't even built the top yet.

The next steps are figuring out some issues around the wagon vise and getting ready to make the top. But that's for next time.

AAAndrew

Monday, February 2, 2009

Roubo Bench - part 1: the beginning

So I finally started getting back into woodworking again and one of the first things I wanted to do was to replace my old bench. What I'm using now I built when I was still back up in Michigan and it's worth describing the bench, what's good about it and what just doesn't work. It's not like we ever need an excuse to build a better bench than what we have, but it does take some extra motivation to move from "thinking about" to actually doing.

The first bench I built was actually based on the idea of doing home fix-it work. It's tall, solidly build out of construction lumber with a top made from layered fiberboard with a hard-board top. It's screwed together and has a peg-board back. Typical tinkering kind of bench. It's in the garage is works beautifully for this purpose. It was while I was looking into how to design and build this bench that I discovered the world of woodworking and got hooked.

I then looked into how to build a woodworking bench. In many ways I lucked into doing many things right, while what I got wrong hasn't been a huge handicap.

What I did right.

I built it to a good height, it holds boards well for end and edge planing with the front vise and a series of holes in the broad front skirt for use with wooden pegs to hold boards for edge planing. It's pretty heavy and doesn't rack too badly. I also made the top co-planer with all of the sides which was better than a dining-room-table-like overhang. Believe me, you don't want the overhang.

What I did wrong.

There's no good way to work the faces of boards. I did improvise a planing stop and have a cheap holdfast so I can do some of that work, but it doesn't work that well. The front vise was not the greatest and is limited for dovetailing and is prone to wracking. But the biggest problem comes from its construction, and my skills at the time.

Let's first look at what it's made of.

I went to the local (Ann Arbor, MI) recycling place and found two old solid-core doors. These were small doors probably for a set of built-in supply cabinets. They were about 5 1/2 feet tall, oak core with walnut veneer. They came with door hardware and little brass label holders. I first took off the hardware, cut the doors to 5 feet (a little raggedy as well) and then built a frame for them out of 2-by construction hardware. I found some 4x4 post legs and notched them at the top and then screwed together the top frame, screwed cleats to the inside and dropped in the doors.

I never squared the rounded edges of the construction lumber, I didn't get the dimensions quite right and as a result the doors sit a little proud, about 1/16", of the surrounding frame, and the gaps between the doors and the frame, about 1/16" - 1/8" are just a trap for shavings and dust.

I also have discovered the short-comings of a wide apron skirt, you can't clamp well to the top. It just doesn't work well to clamp to the edge of the skirt and the 10" skirt is too wide to clamp around it.

Add to that the lack of a tail vise, the rough chop in my existing vise (an off-cut of the 2x10 from the skirt) and it's a barely functional ugly bench. I'm still fond of it in a way as we've been through a lot together. It comes apart and moves easily, but only by unscrewing the huge screws that hold it together.

I really, really needed something that allows me to work to the level I want to achieve. I need heavy, I need the ability to easily work end, edge and face, and I need flat with good clamping surface.

I began to look around for bench ideas. Scott Landis's book was an obvious source and gave me lots of shaker bench envy. I then stumbled across Chris Schwarz's book at a big book store. As soon as I started to read it, the scales fell from my eyes.

The book is clearly laid out, it describes the reasons behind why benches look the way they do, and what the real needs are for a workbench. It then discusses two possible approaches to a workbench with detailed designs and descriptions on how to build the benches.

I read the book cover-to-cover and just knew the Roubo bench was the one for me.

I played around with drawings in Visio (I know, how lame, get with the sketch-up program already, I'm working on it in my copious free time) and got an idea of dimensions based on my limited shop space.

It's pretty much like Schwarz's design in the book including a wagon vise. The dimensions will be:

32" high

24" wide

60" long

Top: 4" thick

Legs: 5" x 5"

short strechers: 3" x 2"

long stretchers: 3" x 3"

Legs mortised into top

Some of the details of the design I've been working on as I go along. I'll share those in the detailed descriptions of each part.

I went to get the wood and decided to go all out and get maple. I found a good deal on soft maple and when I went to order it they told me their soft maple in the dimensions for the top was just not very good quality so they'd cut me a deal on hard maple for the 4"-thick top. Needless to say, I jump at the chance.

So, I purchased the lumber and drove home with a car full of wood and a song in my heart ready to begin.

Next, where to start?

AAAndrew

The first bench I built was actually based on the idea of doing home fix-it work. It's tall, solidly build out of construction lumber with a top made from layered fiberboard with a hard-board top. It's screwed together and has a peg-board back. Typical tinkering kind of bench. It's in the garage is works beautifully for this purpose. It was while I was looking into how to design and build this bench that I discovered the world of woodworking and got hooked.

I then looked into how to build a woodworking bench. In many ways I lucked into doing many things right, while what I got wrong hasn't been a huge handicap.

What I did right.

I built it to a good height, it holds boards well for end and edge planing with the front vise and a series of holes in the broad front skirt for use with wooden pegs to hold boards for edge planing. It's pretty heavy and doesn't rack too badly. I also made the top co-planer with all of the sides which was better than a dining-room-table-like overhang. Believe me, you don't want the overhang.

What I did wrong.

There's no good way to work the faces of boards. I did improvise a planing stop and have a cheap holdfast so I can do some of that work, but it doesn't work that well. The front vise was not the greatest and is limited for dovetailing and is prone to wracking. But the biggest problem comes from its construction, and my skills at the time.

Let's first look at what it's made of.

I went to the local (Ann Arbor, MI) recycling place and found two old solid-core doors. These were small doors probably for a set of built-in supply cabinets. They were about 5 1/2 feet tall, oak core with walnut veneer. They came with door hardware and little brass label holders. I first took off the hardware, cut the doors to 5 feet (a little raggedy as well) and then built a frame for them out of 2-by construction hardware. I found some 4x4 post legs and notched them at the top and then screwed together the top frame, screwed cleats to the inside and dropped in the doors.

I never squared the rounded edges of the construction lumber, I didn't get the dimensions quite right and as a result the doors sit a little proud, about 1/16", of the surrounding frame, and the gaps between the doors and the frame, about 1/16" - 1/8" are just a trap for shavings and dust.

I also have discovered the short-comings of a wide apron skirt, you can't clamp well to the top. It just doesn't work well to clamp to the edge of the skirt and the 10" skirt is too wide to clamp around it.

Add to that the lack of a tail vise, the rough chop in my existing vise (an off-cut of the 2x10 from the skirt) and it's a barely functional ugly bench. I'm still fond of it in a way as we've been through a lot together. It comes apart and moves easily, but only by unscrewing the huge screws that hold it together.

|

I really, really needed something that allows me to work to the level I want to achieve. I need heavy, I need the ability to easily work end, edge and face, and I need flat with good clamping surface.

I began to look around for bench ideas. Scott Landis's book was an obvious source and gave me lots of shaker bench envy. I then stumbled across Chris Schwarz's book at a big book store. As soon as I started to read it, the scales fell from my eyes.

The book is clearly laid out, it describes the reasons behind why benches look the way they do, and what the real needs are for a workbench. It then discusses two possible approaches to a workbench with detailed designs and descriptions on how to build the benches.

I read the book cover-to-cover and just knew the Roubo bench was the one for me.

I played around with drawings in Visio (I know, how lame, get with the sketch-up program already, I'm working on it in my copious free time) and got an idea of dimensions based on my limited shop space.

|

It's pretty much like Schwarz's design in the book including a wagon vise. The dimensions will be:

32" high

24" wide

60" long

Top: 4" thick

Legs: 5" x 5"

short strechers: 3" x 2"

long stretchers: 3" x 3"

Legs mortised into top

Some of the details of the design I've been working on as I go along. I'll share those in the detailed descriptions of each part.

I went to get the wood and decided to go all out and get maple. I found a good deal on soft maple and when I went to order it they told me their soft maple in the dimensions for the top was just not very good quality so they'd cut me a deal on hard maple for the 4"-thick top. Needless to say, I jump at the chance.

So, I purchased the lumber and drove home with a car full of wood and a song in my heart ready to begin.

Next, where to start?

AAAndrew

Subscribe to:

Posts (Atom)