So, I've gotten a couple of weekends of work in and today I was able to finish the leg vise!

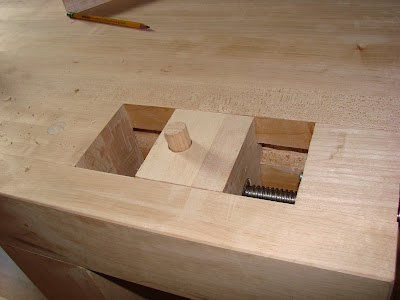

Last time I left off with preparing the vise chop. The next step was to cut the mortise for the parallel guide, drill the holes and pin it to the chop.

So, I drilled the holes for the parallel guide, which is made of Southern Yellow Pine. I got some tearout on the back of the holes, but I figure it's just a parallel guide, so who cares? Right?

I decided to pin the parallel guide in with the brass hinge pins I had used before. They seem to work well for a removable pin.

The next step is to layout the hole for the vise screw and mount it. Simple. Uh, huh.

First I had to clean off the screw and get rid of the tons of gooey, orange packing grease that it came with. I'm still not sure the best lubricant, but I ended up coating it with Boeshield T-9 or whatever it's called. It's a little sticky, so I may end up taking it off in the end and using something a little less high-tech. For now, I'm counting on regular wear and tear to get things moving smoothly.

Then it was time for layout. Having had to learn the lesson of what happens when you rush layout many times in the past, hopefully I've actually internalized it, because this time I took it slowly.

I spent a fair amount of time carefully laying out where the hole should go. I wanted it high enough for strength, but far enough down to be able able to hold some deeper boards in the vise. I eventually placed it so that with the vise screw running through the hole, I have 9" of depth for the board.

I had thought about how to drill the 1 1/4" hole through the chop and the leg. I even went so far as to purchase a drill bit for my (please excuse the language) power drill. Now, I only have a hand-held, cordless drill, but it is a good one, but it was not capable of drilling such a big hole in any test wood.

So, came back to what I should have done to begin with. I sharpened up my #20 bit for my brace, and chucked it up.

To drill the hole I put the chop up on blocks on either end so that it was not resting directly on the bench top. This way when the lead screw of the bit started to poke through, I could feel for it, and it didn't go through my bench. I then held it in my wagon vise.

Test out the hole with the vise screw, and mark the holes for the screw's front mounting plate.

When boring through the chop, I very carefully got the lead screw to come through the back, then flipped it over and finished the hole. When I did this, I worked hard to make sure the plug stayed intact. When you bore with a brace and bit and come in from both ends, if you can work to get it thin enough, the side spurs will cut through before the lip and you'll end up with a plug.

If you can keep this, it's a great little helper for figuring out the center of the big hole. I just put the plug back in when I clamped it to my bench leg and it allowed me to find the center of the hole on the chop. Stick my awl in the hole, give it a light tap with my mallet and you've got a great place to start boring.

Put the parallel guide back in, line up the chop on the leg so that it's flush with the top, and the parallel guide works smoothly. It was not that easy, but it can be done. It would be easier with two people.

I used the plug to mark the spot and then very carefully, checking for square every few strokes for the first 1/2 inch, I began to bore through the leg.

Even with a rather long bit, that is still a lot of leg to get through.

So, I get through to the point where the lead screw is just poking out the inside of the leg. Normally, you flip the piece around and begin boring again from the inside to avoid tearing out chunks as the bit comes through. But I have a problem. The brace and bit are too big to fit in between the legs.

If I had one of those fancy 90-degree big conversion things, I could do it, but I don't. So I had to figure out some way of getting at least past the surface so as to avoid tear-out.

I ended up resorting to the only power tool to be used on my bench. I got that bit I had bought for my cordless drill and the drill and started to work on the inside.

What I had to do was to strip out the center hole so that the lead screw on the bit wouldn't bite. Whenever it did, it would pull the bit right into the wood and it would freeze up.

Eventually, by running the bit in reverse and pushing it in and out, I stripped out the center hole enough that it didn't bite anymore. Later I figured I could have also drilled it out, but whatever works at the moment. Once it was no longer biting, I could very slowly and gradually work the bit into the wood so that it wasn't freezing up by biting too deeply, but was eventually able to break the surface enough that I could come in from the original side and not get tear-out.

After that it was a matter of mounting the vise hardware, and putting it all together.

And it clamps! Really tightly!

As you can see in that last picture, my parallel guide is being held with a rather unorthodox pin. I'm using a hook bolt. I like that it has a little hook which I can just grab and pull out. It's what I'm using right now. We'll see if I keep using it.

The final dimensions that I can clamp are 9 1/2" depth of clamping, and 9" tall.

The next step will be to dismantle my old bench and free up room to finally work with my new bench only. After that I'll make the deadman and the planing stop. But I needed the leg vise to make the deadman.

Finally, it really is not just looking more like a bench, it now actually functions like one.

Wooo Hoooo!

I'm trying out how well this works by coming directly from Picasa. I'm more interested in how I might be able to get larger pictures into my blog. Can I get more than 400 pixels wide?

I'm trying out how well this works by coming directly from Picasa. I'm more interested in how I might be able to get larger pictures into my blog. Can I get more than 400 pixels wide?